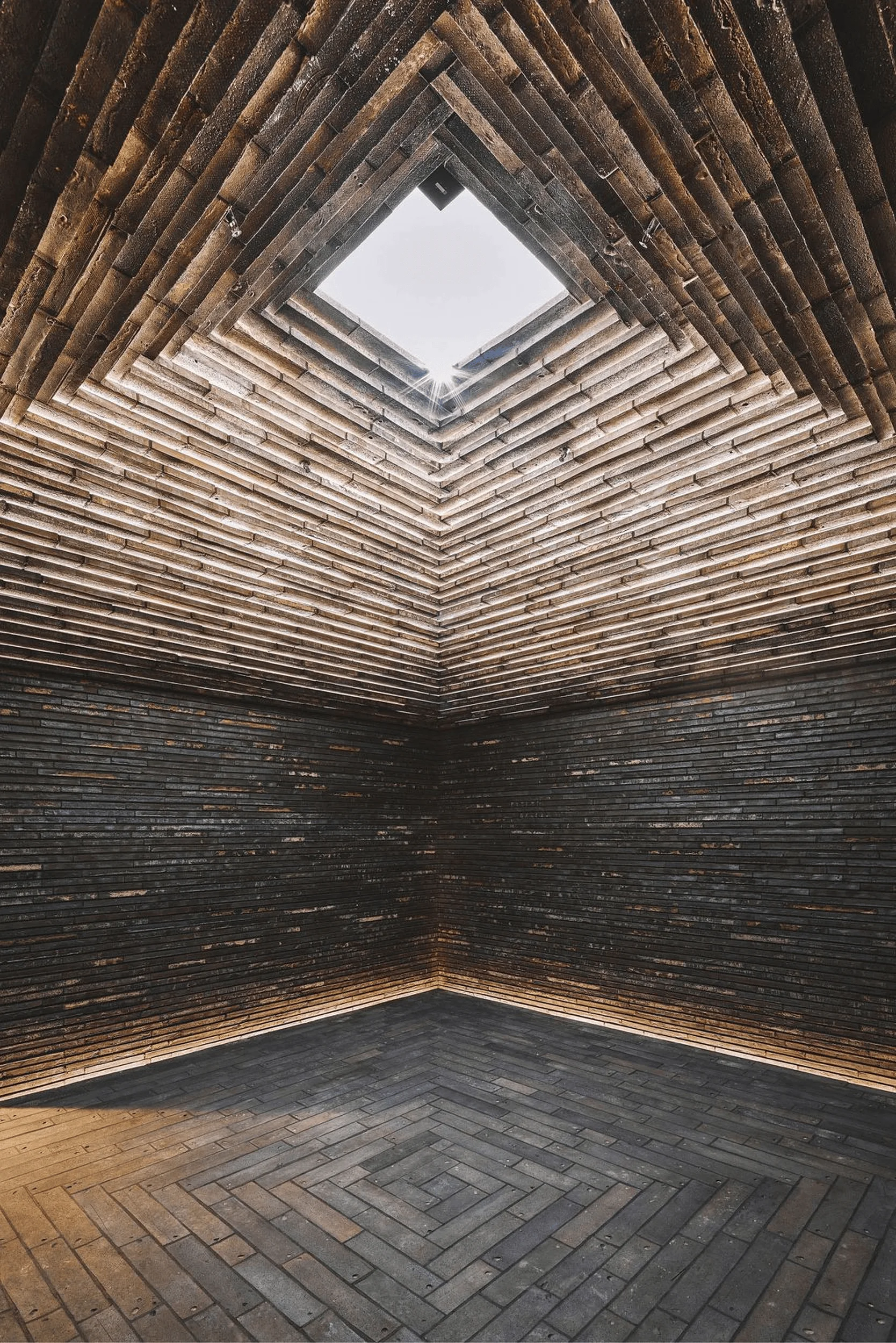

The Steam Punk Pavilion, designed by Gwyllim Jahn, Cameron Newnham (Fologram), Soomeen Hahm Design and Igor Pantic, with structural design by Format engineers, is a temporary architectural installation for the fifth Tallinn Architecture Biennale (TAB 2019) in Estonia. The pavilion will remain in place until the next biennial in 2021. As designers of the Steam Punk Pavilion, we did not use CNC machine technology, nor did we output the individual components of the design as graphic data for auxiliary cutting, printing or connecting. Instead, we propose another experimental approach to architectural implementation, discussing the controversy of this method of construction in the current environment of robotic production and automated manufacturing. Automation and robotics give architects unprecedented possibilities. We can fully control the realization of every detail of the building. However, the subtle and refined beauty found in traditional handcrafted work is absent in robot-made products. The reason is that the human instinctive understanding of the quality and quantity of objects cannot be translated into the simple, direct code language of robots. We want to explore a dialogical way of building that combines the precision and flexibility of using digital models. At the construction site, we will present the digital models directly in the form of holograms. The workers will be guided by these holograms to use relatively primitive analog tools in conjunction with their hand skills and creativity to achieve a precise and complex construction process. This approach deliberately ignores some of the material properties that must be fully considered in digital models, allowing the construction to achieve a certain degree of inaccuracy. Many material properties are only discovered, become effective, or are amplified at the construction site. This approach liberates digital expression from the inherent pattern of digital manufacturing, while combining it with the refined feel and materiality of handcraft, ultimately realizing the main design concept of the pavilion. The pavilion is located in the center of the Biennale’s central lawn, where it directs the views from the four zones of the exhibition area towards Tallinn’s old town and the Architecture Museum. Wooden strips measuring 100x10mm are twisted three-dimensionally along the fiber direction to create a multi-layered shape. This way of building using unified size materials is more like weaving than assembling, weaving a shell structure combining wood and steel. The curvature of the wood section will increase the material’s hardness and pressure resistance. The study of the lines of the woven wood strips decomposes from a traditional net-like surface structure to a simpler topological geometry, transforming the blurred shape of the nodes, either inside or outside, or surface or shape. To achieve a stable light-weight shell structure, the pavilion’s spatial design utilizes the coordination of positive and negative space, forming an intimate interior space through the bagged solid structure. The bar-shaped components in the wood structure are made using a rare and extremely complex steam bending technique. Each bar-shaped component undergoes a bagging, steaming and bending process, where the wooden strips are bent on a transformable model according to the holographic image. This manufacturing process provides two forms of feedback: one is the holographic model providing the workers with a clear visual effect, ensuring the precision of the manufacturing, the workers can also follow their own feelings and adjust the model position through handcraft skills, realizing the manufacturing within the allowed range. Secondly, the physical shape formed on site will be scanned back into the digital model, allowing the designers to make necessary adjustments to the overall model. Each construction and feedback is a direct collaboration between designer and maker, a communication about the anticipated process and the resulting outcome. The beauty of this project lies in the design tension that arises from the manufacturing process, from every choice made by the designer and the maker, when to insist on grasping the original design intent and when to abandon precision and begin to recreate.

Project Information: